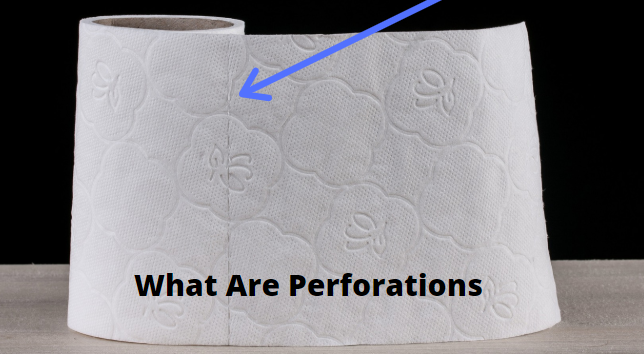

Perforations are a small detail many people don’t take note of throughout their day-to-day activities, but they are a tool that provides ease and convenience. A perforation is a small hole or row of holes punched into a material — commonly found on paper, plastics, and packaging products — so a part of it can be easily torn off. The purpose of a perforation is to make a material easy to tear or bend.

Benefits of Perforations

With perforations, you can streamline daily business tasks and operations and enjoy a range of flexible uses you likely never even considered. Several advantages of using perforations in paper, plastic and packaging products include:

- Easy, clean tearing capability: Labels and other items that are directly printed on perforated paper means they are faster, easier and cleaner to tear apart. While you can purchase perforating tools, paper that is already perforated can save you time and money, while minimizing inconsistencies for a more professional appearance.

- Versatile usage: There is a wide variety of uses for perforations. Perforations are used frequently in the plastic, paper, and packaging industries.

- Tidy storage options: Perforated materials are generally easier to store than other products. For example, a roll of paper towels is easier to store and handle than a pile of individual paper towels. This is made possible from the perforations in the roll.

Perforations in Everyday Life

Paper perforations are the handy little tool you never knew you needed or regularly relied on. Take a closer look at your surroundings, though, and you’ll find perforated paper is used in a wide variety of different everyday items, including:

- Rolls of trash bags

- Bubble wrap rolls

- Food packaging, such as the “tear off” section of a box of crackers or the slits on a pizza box

- Tear off boxes for displaying products on a store’s shelf

- Boxes used to hold bags of liquid, such as boxed wine

- Movie and raffle tickets

- Coupons and gift certificates

- Stamps

- Notebooks

- Checkbooks

- Business cards

- Toilet paper and paper towels

Perforated paper products are an upgraded and useful tool that provides functionality and convenience while also helping consumers and businesses save time and money.

How Are Perforations Made?

Perforations are simple to use, but they are created with an effective and sophisticated process. To manufacture a product that uses perforations of different sizes and lengths, professionals use a specific machine with specialty knives that accurately and precisely make vertical cuts along the backing of the material. At York Saw & Knife, we manufacture a wide variety of different perforation knives for several different industrial applications. Our selection of perforating knives includes straight and cutoff blades as well as circular perforating knives. They are available in a range of cut sizes, tooth heights and depth edges. Our perforation knives are specially crafted from the highest quality materials, including high carbon, solid carbide and stainless steel, for lasting precision, reliability and performance.

Explore our wide selection of perforation blades today and reach out to our team of knowledgeable custom knife experts for guidance on which products and materials will work best for your business applications.

York Saw & Knife — The Leading Manufacturer of Custom Perforation Blades

York Saw & Knife has the most extensive selection of custom perforation knives and industrial blades for a variety of different uses. Our team is happy to work with you to find the personalized solutions that are best suited to your daily and long-term operational needs. Learn more about our perforation tools or begin designing custom blades today by filling out our online contact form or calling 800-233-1969 to speak to a team member.