Complete Guide to Sawmills

Wood is one of the central elements of our lives. Wood supports our homes and the roofs over our heads. We eat on wooden tables, cook with wooden spoons and enjoy the architectural detail of wooden cabinets. We even place our paintings in wood frames. Yet many people take wood for granted, never stopping to think how we get the wood that is a foundation for many things in our lives.

If you want to know how sawmills process wood, this complete guide to sawmills will provide all the information you need. Learn about the sawmill throughput process and how raw logs turn into finished wooden products. We’ll answer questions like:

- What happens in a sawmill?

- Who invented the sawmill?

- What are the types of sawmills?

- How do you choose a sawmill blade?

- What is the largest sawmill in the United States?

- What sawmill terminology should I know?

Things have changed since the old days when sawmills required manual labor and brute strength. The original sawmills were dangerous places. Today, sawmills rely on highly technical systems and computerization to maintain high production. At York Saw & Knife, we’re proud to supply high-quality blades to enhance modern sawmills’ power and efficiency through Oleson Saw Technology. If you would like to learn more about sawmill blades now or find that you have more questions along the way, reach out to us at 1-800-233-1969, and we’ll be happy to assist you.

Table of Contents

Chapter 1: What Is a Sawmill?

The term sawmill could refer to two different concepts within the industry. The first is a location where people mill lumber. The sawmill is all the land on which the sawmill sits — the log sort yard, milling machinery and the area where wooden planks are sorted and stored. A sawmill also has areas on-site for the mill’s administration and maintenance.

A sawmill also refers to the specific cutting or sawing mechanism. These machines turn round logs into rectangular timbers for use in manufacturing. Technically, the sawmill industry calls the core sawing machine a head rig, but the head rig needs an extensive support structure to function correctly. Perhaps the most accurate definition of a sawmill is that it’s the entire system that turns logs into lumber.

Whether you use the word to refer to the individual sawing machine or the entire lumber milling operation, sawmills are inherently bustling places. Most modern sawmills are enormous commercial enterprises with high productivity. Some of these locations employ hundreds of workers and schedule rotating shifts around the clock to keep lumber production efficient.

When Was the Sawmill Invented?

Prior to the invention of the sawmill, people cut, split and planed wooden boards by hand using hand tools. Later, people used a whipsaw, a long blade that cut logs as men pulled the saw. This process was tedious and tiring and needed improvements.

The history of sawmills dates back to the Roman empire. The first known sawmill is called the Hierapolis sawmill and dates to around the third century A.D. The sawmill was discovered when archaeologists examined the sarcophagus of a miller in modern-day Turkey, what used to be Asia Minor. On the sarcophagus was a raised relief of a waterwheel with a crank slider mechanism and two saws cutting through blocks.

The Roman waterwheel-powered saw represented a significant advancement in engineering and production. Around the sixth century, water-powered stone sawmills were popping up throughout the Byzantine Empire. By the 11th century, these sawmills spread from Spain and North Africa to Central Asia.

Who Invented the Sawmill?

The design of the sawmill remained essentially the same until the Industrial Revolution, when someone invented the circular saw blade. Historians typically credit Samuel Miller, who was awarded a British patent for the blade in 1777. Others claim the Dutch developed it in the 17th century or that it was the American Shaker Sister Tabitha Babbitt. Whoever invented it, the bandsaw’s high price and inferior blades meant it wasn’t used widely until the middle of the 19th century. Today, most sawmills use industrial-sized band saws.

What Can I Get at a Sawmill?

A sawmill can produce high quantities of all kinds of lumber, although most sawmills specialize in a specific type of lumber. Sawmills in North America process one of two kinds of trees, softwood or hardwood.

Softwood trees are evergreens or conifers with permanently attached needles. These species include cedar, pine, spruce, hemlock, fir and redwood. Hardwood trees are deciduous species that shed their leaves in autumn and produce new ones in spring. Species like walnut, maple, beech, cherry, elm and oak are all hardwood trees.

These species require different machines and tools to process. Some sawmills buy the equipment to process both types of trees, although this is uncommon. You can generally find softwood materials in rough carpentry and building framing, which light commercial construction industries use. Residential construction uses hardwood lumber for finished products like furniture, flooring, staircases and plywood panels.

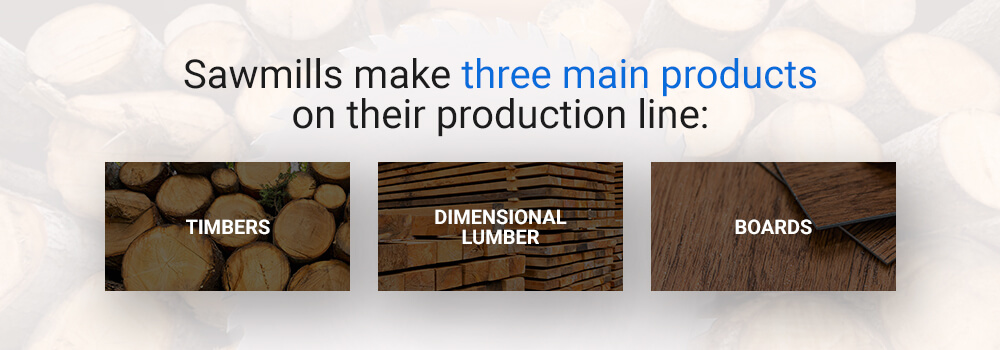

Most sawmills make three main products on their production line:

1. Timbers

Timbers are large-cut posts used in construction. These products measure over 5 inches thick and provide essential structural support. Construction companies use timbers as beams or posts when building projects like houses or barns.

2. Dimensional Lumber

The most common product coming off the sawmill production line is dimensional lumber. These wooden planks are smaller than timbers and measure according to standardized sizes. For instance, dimensional lumber can be between 2-5 inches thick and 2-12 inches wide. Standard sizes for dimensional lumber include two-by-fours (2x4s) and four-by-fours (4x4s). Many construction and manufacturing applications use dimensional lumber for joists, studs, headers, plates and rafters.

Sawmills also plane dimensional lumber to a specific size and smoothness. Dimensional lumber sizing can be somewhat tricky, as planing the wood reduces its size slightly. A rough-cut plank coming from the head rig is precisely 2 inches thick and 4 inches wide. However, the actual dimensions of a 2×4 exiting the sawmill’s planer are 1 ½ inches thick by 3 ½ inches wide.

3. Boards

The third type of lumber product made at a sawmill is the board. Boards are thin planks that usually measure between ¾ of an inch and 1 inch thick. Boards can range from 2-12 inches in width. Companies use boards to form plank floors, sheathing structures and frames for furniture. Rough-cut boards work well in pallets and crates.

Other products you can find at a sawmill include wooden planks with specialized shapes and contours. Sawmills can produce interlocking tongue and groove shapes, shiplap edges and rounded profiles. All of these planks are used in decoration and architecture. Some sawmills will also custom-make orders according to the customer’s specifications. Select locations will also source wood from foreign or local markets.

What Are the Types of Sawmills?

Depending on the production needs, sawmills can either be stationary or portable. Stationary sawmills are large-scale constructions in fixed locations and mounted on a foundation. Portable or mobile sawmills are smaller productions and might be mounted on a truck or trailer. These sawmills range in size and are designed with certain specifications to fit their intended purpose and production level. Each type of sawmill can also accommodate different numbers of operators or workers.

Stationary sawmills are often built near water sources. Historically, this placement made production easier. Most sawmills during the industrial revolution were powered by steam, which required a stable and renewable source of water for production. It was also practical to have the mill near a waterway so employees could use the water to transport logs to and from the mill. Storing logs in the river or lake prevented them from drying out prematurely.

Modern sawmills don’t use steam. However, many sawmills remain in the same location as their predecessors. These sawmills have evolved, but they are still built near water. In contrast, portable sawmills don’t require a source of water or a specific amount of land. The operators can move these machines between sites whenever they need to.

Sawmill types are also categorized by the type of blade they use. Most modern sawmills use a combination of blade types, including circular blades and band saws. Consider the differences between the two blades:

- Circular blades: Circular sawmill blades can efficiently perform cross-cuts or buckle logs into the desired length. These blades also tend to be thicker than band saws, giving them additional strength. Their design leads the saw kerf to create more waste.

- Band saws: Band saws are excellent for cutting logs laterally. Band saw blades are thinner with thinner kerfs. These blades increase sawmill efficiency by creating less waste during the wood finishing process.

The changing technology of saw blade construction benefits every sawmill. For example, companies have developed superior products like Stellite™-tipped blades and tungsten carbide to replace old-fashioned materials. These new saw blades last longer than hot- and cold-rolled steel and provide greater efficiency.

How Are Sawmills Powered?

As with most forms of technology, a sawmill’s power source has evolved significantly over the decades. The initial mills had waterwheels, which gave way to windmills. Both of these systems were subject to changes in the weather. Workers couldn’t operate the sawmills if a water source dried up or the wind stopped blowing. These types of sawmills also used inefficient cranks and rods that didn’t saw continually.

In the early and mid-19th century, steam was the primary source of power for sawmills. Sawmills could reuse their wood waste by using the scraps to fuel the steam boilers. The boilers powered turbine shafts, which turned the circular and band saw blades. These boilers were used primarily because of the abundance of wood waste, so oil-fired burners never became widely popular.

By the middle of the 20th century, most stationary sawmills phased steam power out and replaced it with electricity. This power source continues to be the primary source in effect today. Portable sawmills typically don’t use electric power since the mill sites that use them are usually off the electric grid. Instead, mobile sawmills use diesel and gasoline power sources. There is currently no serious shift toward solar power sources for sawmills since the production process requires vast amounts of energy.

Besides turning blades and conveyors, sawmills also need power for other systems. Modern sawmills use computers to scan logs and determine the optimal cutting efficiency. The computer systems then send the digitized information to the sawmill components to meet daily demands. All of these advanced processes require electric energy.

How Does a Sawmill Work?

Modern sawmills operate in essentially the same ways they have for hundreds of years, just more efficiently. The mill takes raw lumber and sends it through mechanized steps that refine and smooth it until the finished product emerges. Modern sawmills increase throughput through automation. This process is an on-demand system that takes wood from front-end loggers and makes it ready for the tail-end marketplace.

The sawmill lumbering operation involves several stages. Despite technological advancements and increased use of sophisticated computerization, modern sawmills still rely on experienced sawyers. These workers use their sharp eyes and quick movements to direct lumber efficiently. Here are all the steps a sawmill takes to get the job done:

- Felling: The first step in sawmill production is to cut the trees. Loggers on the front end of the process fell standing trees from second- or third-growth woodlots because there are few original, old-growth forests in America today. Loggers primarily use gasoline-powered chainsaws to cut trees before loading and transporting them to the sawmill. Other tools for felling trees include feller bunchers.

- Debarking: Once the logs are on-site at the sawmill, they must be debarked. Most sawmills use machines like mechanical ring cutters to strip each log of its bark. Others use water-jet blasters. Whatever method they employ, sawmills keep the bark waste to use as landscaping mulch or to fuel the kilns. In the debarking stage, a circular saw will buck or cross-cut logs into the correct lengths.

- Metal detecting: Sometimes, standing trees have pieces of metal from nails or fencing wire embedded and covered by years of growth. It’s vital for sawmills to examine logs for metal contamination before sawing them. Undetected scraps of metal can ruin blades or send shrapnel flying. If a log contains metal, it goes for a second examination. Depending on whether the metal can be removed, a log returns to the production line or is cut into smaller pieces for salvaging.

- Merchandising: Modern sawmills use computer processes to merchandise logs before sawing them, a critical step for peak efficiency. Computers use camera viewing or laser scanning to estimate each raw log’s maximum cut value by measuring the length and girth. The system then determines which sizes of boards, dimensional lumber and timber the log can provide. The merchandising step also assesses logs according to standing orders and market conditions.

- Head rig sawing: Logs are clamped to the conveyor and move to the head rig for sawing. Some sawmills have conveyors in a stationary carriage, which the head rig moves over with its blades while it saws the log lengthwise. Other locations use a fixed head rig that cuts the log as it moves along a mobile conveyor. With either method, head rigs are typically fitted with band saw blades. Technologically advanced head rigs follow the log’s natural curve.

- Canting: As the head rig cuts the log, it creates sections called cants. The first breakdown creates a flat surface the head rig can use to square the workpiece for secondary cants. This breakdown is called the best opening face. After this, secondary cants turn the log into rough sizes for the lumber products. Any waste slabs are recycled into mulch, pellets or chips.

- Resawing: The large cants that the head rig creates go to the resawing process. In this step, several band saw blades cut the cants into smaller pieces according to the merchandising instructions. Resawing can create many profiles, including twin or quad bands, horizontal and vertical bands, band center splitters, circle gangs, double arbor gangs, band line bars and more. The resaw step also uses curve sawing to get an accurate profile.

- Edging and trimming: The newly-cut timbers, dimensional lumber and boards have their edges cut to the correct grade size. The products continue to a trimmer, which cuts the specific lengths. Most sawmills cut wood products in 2-foot increments starting at 8 feet and going to 24 or more.

- Grading, drying and planing: Finally, the products go through the quality control process. Grading is essential for ensuring lumber pieces emerge in batches of similar products. Then the sawmill dries the lumber to reduce its naturally high moisture content. Lumber products are either air-dried or force-dried in kilns. After that, planers create the products’ ultimate appearance and size. Then the products are marked with finished grade stamps and bundled for shipping to market.

Where Can I Get Sawmill Supplies?

York Saw & Knife has supplied top-quality saw blades to American sawmills for over 100 years. We are your best source of sawmill supplies to keep your sawmill sharp and working efficiently. You can find our industrial machine knives and precision saw blades in some of the most productive stationary sawmills in the world.

Our Oleson Saw Technology division designs and manufactures a complete custom sawmill blade line. Whether you need variable pitch (VPD) circular or wide band saw blades made from carbide or Stellite™, you can find them at York Saw. You can also find a wide selection of tooth patterns and sets, along with other sawmill supplies for every application.

Check out our sawmill products today or contact us online for more information. You can also call us at 1-800-233-1969.

Chapter 2: Portable vs. Stationary Sawmills