Chapter 4: Sawmill Blade Sharpening and Filing

It’s crucial to keep sawmill blades sharp. Otherwise, a dull blade will not work effectively and will slow down production. When production slows, industrial sawmills lose time and money. Blades should be able to cut through the material effortlessly.

Although sharpening a blade can sometimes solve the issue, you may need to replace the blade depending on its condition. In this chapter, we’ll show you when it’s time to change the blade, what sharpening and filing entails, and who to ask for assistance.

When to Replace a Blade vs. When to Sharpen

Naturally, you want to get the most value out of your sawmill and avoid replacing the blade if possible. You may only need to sharpen the blade if you notice greater resistance when you feed workpieces into the mill or if the blade burns the wood more often. The blade may merely need cleaning if you find buildup on the sides of teeth tips.

Generally, an industrial mill will sharpen a few inches off the blade width before the company replaces it. Industrial mills sharpen their blades as often as every few hours to ensure max cutting performance.

You should be able to sharpen your blade two or three times before needing to replace it, but sometimes breakage happens. Blade breakage can result from a range of situations. Common causes of blade breakage include:

- Dull teeth

- Damaged teeth

- Feeding the wood too fast

- Running the band saw when not using the machine

- Using the wrong tooth pitch

- Not adjusting or aligning the blade correctly

Factors such as how long you use the saw, how it’s used, and the quality of the blade determine how long it will last. If there is a noticeable safety concern or a crack or bend in the blade, it’s time to replace it. Other signs you may need to replace the blade include:

- The blade takes more effort to cut

- The blade burns on wood

- It’s hard to follow cut lines

- The saw machinery is louder than usual

- You notice chipped, broken or missing teeth or obvious signs of damage

If you’re not sure how to determine the condition of your blade, it might help to remove the blade from the machine and compare it to an identical blade that’s in excellent condition.

Sawmill Blade Filing and Sharpening

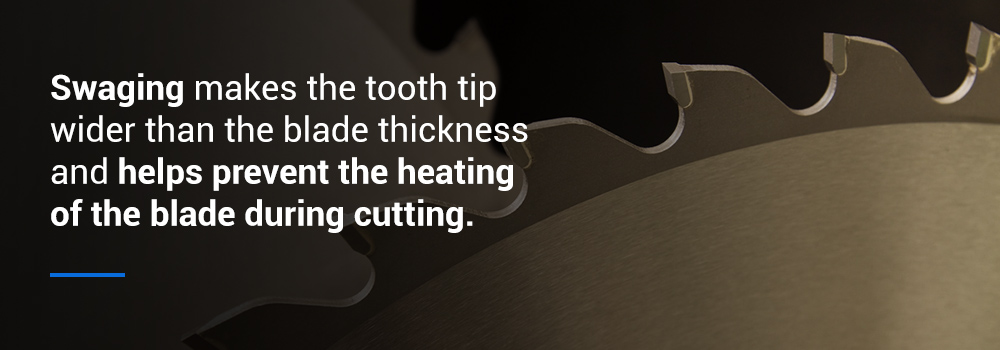

Proper blade maintenance and treatment extends its life and enhances its performance. Sharpening is a major component of blade maintenance. Band saw blades must be swaged before they are sharpened.

Swaging makes the tooth tip wider than the blade thickness and helps prevent the heating of the blade during cutting. The Iseli STA Automatic Swage and Shaping Machine is an automatic swaging tool for band saw blades. According to Oklahoma State University, the rule of thumb is to swage the blade to twice the thickness of the plate, and to add one gauge when cutting through green, or undried, lumber.

After swaging, band saw blades are then sharpened by grinding, often with an abrasive aluminum oxide wheel and sharpening machine. The sharpening tool must be run at the correct speed to prevent blade damage. The proper wheel thickness also ensures adequate sharpening. In general, the sharpening wheel should be around half the length of the tooth pitch in thickness.

You can also sharpen a blade manually by applying a Dremel tool to the tip and gullet. Manually sharpening a wide band saw blade can be a time-consuming process and requires a steady hand. Industrial sawmills, which need regular sharpening to boost efficiency and reduce downtime, greatly benefit from the use of grinding machines.

Grinding machines are specially designed for sharpening industrial band saw and circular blades. Most industrial mills own this equipment in-house. Some people who own portable sawmill also have this in their shop and help serve others with it. Saw shops often have this equipment.

Filing Services for Sawmill Blades

At York Saw and Knife Co, Inc., we’re here to help you accelerate the blade sharpening process so you can keep production levels high. To learn more about the state-of-the-art blade filing and sharpening machines we distribute, contact us today.