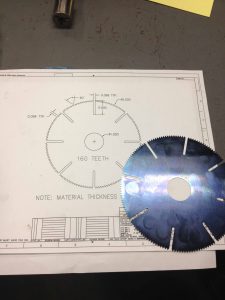

In an earlier post, we told you about one of the first steps in our manufacturing process, reverse engineering. This week we are going to explore what happens next. After the drawings of the blade are approved by the customer, the next step is to laser cut the blade out of the raw material. We utilize a Trumpf Laser 2025 for the most precise cut possible. Below are pictures and video of this process!

What Is Laser Cutting?

Laser cutting is a non-contact fabrication process that uses a high-powered laser beam to cut metal and non-metal materials into specific shapes and designs. Many industries prefer using laser cutting technology because it is highly accurate and produces excellent cut qualities, making it possible to make intricate shapes or small holes.

There are several types of different laser cutting machines including gas, liquid and solid state lasers — the most common laser mediums are CO2 and Nd:YAG, operated either using a continuous wave beam or pulsed beam. At York Saw & Knife Co, Inc., we utilize a CO2 laser for all of our projects to ensure accuracy and efficiency.

The Laser Cutting Process

During the laser cutting process, the laser beam is precisely focused on the material, piercing it through its edge. Then, the laser beam is guided along the material’s surface, slicing through it and delivering an accurate and smooth finish. While this process is referred to as laser cutting, the laser is actually melting the surface of the material versus cutting it.

For CO2 lasers, the cutting process is completed using a continuous beam gas laser. The CO2 gas mixture is electrically stimulated. CO2 lasers are one of the highest-powered continuous wave lasers available for laser cutting today.

How York Saw & Knife Co, Inc. Laser Cuts Blades

At York Saw & Knife Co, Inc., we use a very detailed, precise laser cutting process for all of our blades, following these exact steps:

- Develop a meticulous computer rendering of the materials needing to be laser cut.

- Set up our Trumpf Laser 2025 to begin cutting the metals according to the precise engineered drawings.

- Evaluate the final cut product against the initial engineered plans.

Explore Our Wide Selection of Laser Cut Blades Today

Streamline your operations with quality laser cut blades and knives courtesy of York Saw & Knife Co, Inc. All of our products are specially designed and developed for long-term, dependable and efficient use for a variety of different industries. Check out our selection of knives and blades today, available in small or bulk quantities to suit your specific needs. For additional information about our laser cutting products and associated products, contact us today.