If you rely on knives for your manufacturing processes, you understand the importance of high-quality, durable products designed for specific applications. You know that different procedures require different tools and why specialized knife options are critical to your success. Knife technology has evolved tremendously over the years to meet the increasing demand for high-quality yet cost-effective knife blades for specific industrial applications.

This creates challenges and forces knife makers to come up with creative cutting solutions. Today, knife design and manufacturing experts like York Saw & Knife use advanced high-carbon alloys, ceramic blends and even spring steel for specialized knife blades to meet the needs of customers across America and around the world. Whether you’re an original equipment manufacturer (OEM) or an end user, York Saw & Knife will work with you to choose a knife for your industrial application.

The Importance of Choosing Knives for Industrial Applications

All industrial cutting applications have unique and specific requirements. At York Saw & Knife, we understand the importance of choosing the right knives for every industrial application and situation. We also understand the importance of building blades to exacting tolerances so your business thrives and prospers. We know how to make the right knife for you because we’ve been making custom knives in York, Pa., for more than 100 years.

If you’re an OEM, you want reliable cutting solutions that are consistent, cost-effective and have a fast turnaround time. It’s highly important for you to work with a company that specializes in manufacturing custom industrial knife blades. Therefore, it’s vital for us to thoroughly understand your precise needs to build you a made-in-U.S.A. knife that fills your OEM requirements. We do that by listening to you and cooperating through our engineering design team.

If you’re an end user of precision industrial knives, you also want economical solutions for replacement knives without having to go back to your original equipment manufacturer time after time. At York Saw & Knife, we work with many national and international machine knife end users. Our engineers and designers know that it’s important for end users to get the same quality service and products that their OEM sourced while manufacturing their equipment. We also fill your end user needs by working with you to choose a knife for cutting whatever it is your company produces.

Being centrally located in York, Pa., we’re well positioned to serve customers like you no matter where in the world you do business. Our innovative manufacturing processes and capable engineering team allow us to design and make machine knives for virtually all industrial cutting applications. We feature some of the fastest lead-to-response times in the knife blade manufacturing industry. We also offer free test cutting and have no minimum orders. York Saw & Knife understands how important choosing your industrial knife blades are to your business, which is why we assure quality as well as financial savings with every order.

Common Machine Knife Blade Industry Applications

Over the years, we’ve designed and manufactured machine knife blades for practically every conceivable industry. Some of the unique applications involved paper tube saws for the foil wrap industry, carbide cutoff saw blades for the furniture industry and pouching machine blades for the pet food industry. We’ve produced many food processing knives, meat-cutting machine blades and custom packaging knives as well as warehouse knives and fiberglass knives. What we produce depends on what you, the customer, truly require.

There are no out-of-the-ordinary requests for York Saw & Knife. We look at each customer’s overall requirements and then work together to design, manufacture and test each individual cutting product. Some of the more common industry applications that we make precision blades for include:

- Food Processing: The food processing and food packaging industry demand a considerable variety of specialized blades and knives. Common knife applications find their way into processing meat, chicken, fish and seafood. Companies processing and packaging dairy products and baked goods also have demands for our blades in their applications. So do businesses that process and package fruits and vegetables.

- Automated Packaging: We design and manufacture many specialty cutting applications for the automated packaging industry. Applications include job-specific requirements for horizontal and vertical form fill, case sealing, wrappings and pouches. Examples of specialty blades for automated packaging have tear notch, zig-zag and easy tear features that allow for flexibility in their application.

- Converting: Common applications for blades made by York Saw & Knife are trimming, scoring, slitting and perforating materials. Converting uses include cut-offs for winding and rewinding web applications. This is common to industries involved in printing and laminating as well as processing non-woven materials including fiberglass insulation.

Many other industries depend on York Saw & Knife for making custom blades. We have a broad capability to source many different materials used in specialized knife making. We also have the in-house equipment to manufacture blades and specific knives to precise specifications and tolerances.

Additionally, we have experienced professional staff who know the industry intimately and can provide you with the perfect cutting solution. It’s this combination of industry knowledge, metallurgical understanding and ability to design and produce cutting products with complex computerized machinery that give you the best possible options. Our most popular machine blades include:

- Straight Knives

- Circular Knives

- Cutoff Knives

- Tray Knives

- Fiberglass Knives

Each of these five machine blade categories has specific designs and purposes. To help you choose the best knife for your industrial application, look at each popular knife type and what they’re intended for. That includes what materials you can expect to be used in the knife blade, what configurations are suggested and what industries you would expect to employ this type of knife.

Here is a detailed review of the top knife designs we manufacture at York Saw & Knife. You’ll likely find exactly what you’re looking for. However, if a common knife type doesn’t fit your needs, we can always design and manufacture a custom application. That is part of the overall service we provide to our valued customers at York Saw & Knife.

Straight Knives

York Saw & Knife produce straight knives for those who want durable and high-quality cutting tools for industrial applications. Beveled straight knives are important for OEMs who need cost-effective stock blades. Straight knives are also essential for end users looking for specific applications. Both customer profiles realize how important getting the right knife at a fair price is to their business. To fill that void, York Saw & Knife responds with economical and versatile solutions.

Beveled straight knives are cost-effective performers because of a balance between hardness and toughness. Don’t be confused into thinking the two terms mean the same thing:

- Hardness: The knife blade density, which is measured on the Rockwell scale.

- Toughness: The blade’s resistance to erosion, which is measured by its Transverse Rupture Strength (TRS) or flexural strength.

A well-balanced blade is hard enough to resist breaking and tough enough to stay sharp.

Straight knives are the most popular and versatile way of cutting for most industrial applications. Often, you’ll find straight knives used for both woven and knit fabrics. Industries processing materials from steel to food choose straight knives for their cutting tasks. These can be anywhere from small to large applications. Some industries commonly using straight knives include:

Choosing the proper material is crucial in making high-quality straight knives. Materials dictate blade longevity, and metal compositions determine how a blade will react or degrade with the product being sliced. Here are material choices you have with straight beveled knives manufactured by York Saw & Knife:

- High Carbon

- Stainless Steel

- Solid Carbide

- Ceramic

- CPM 10V

- 52100

- M-2

- D-2

York Saw & Knife can provide you with precisely the right straight knife for your industrial application. We can duplicate your existing knife configuration to precise specifications including the exact hardness and toughness you require. We also have full capabilities to custom design your next straight knife. Call us at 800-233-1969 to discuss your custom straight knife options. We’ll get an idea of what you’re looking for in straight knife design and offer you a quote.

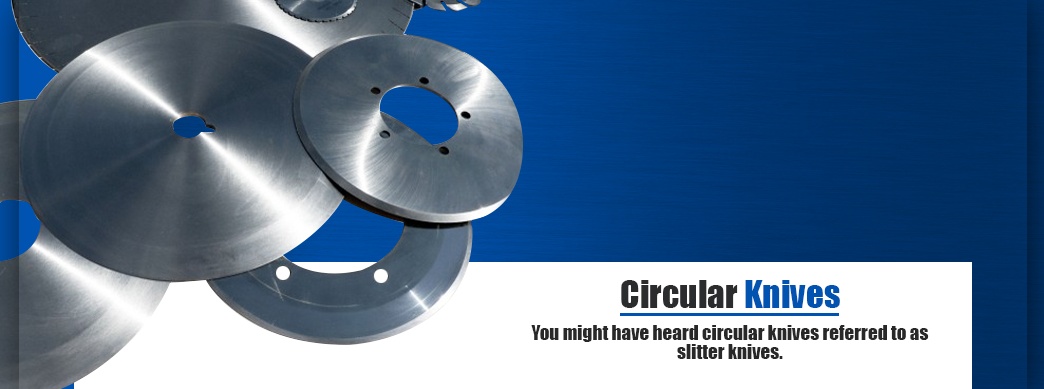

Circular Knives

You might have heard circular knives referred to as slitter knives. Slitter is a common term for beveled and toothless circular knife blades because of their primary application for slitting a massive range of materials. Circular blades are also used for scoring, creasing, perforating, slicing, trimming and cutting applications.

Many industries find circular blades to be highly important for specific tasks. York Saw & Knife realizes how important circular knives are for processing stone, glass, concrete or other tough materials. Industries find delivering high accuracy important for creasing materials no matter how strong they are. Other important uses for circular or slitter knives are trimming textile fabrics and cutting foil, food, film, steel and more.

York Saw & Knife circular machine knives are excellent choices for many cutting, scoring and slitting jobs. York provides common styles and standard circular knife configurations. We also design and manufacture top-notch custom blades for many different geometric edge shapes. These are some of the circular knife blade styles we produce that hold optimum cutting edges:

- Square Edge

- Single Bevel Blunt

- Single Bevel Sharp

- Double Blunt

- Double Sharp

- Double Single Blunt

- Double Single Sharp

- Double Double Blunt

- Double Double Sharp

Besides a wide range of cutting styles, we offer you a great choice of circular knife tooth configurations. We manufacture circular blades with serrated edges as well as toothed cutting edges. You have a choice of standard “L” style teeth or scalloped edge designs. With York Saw & Knife, you have access to regular machine blades with circular configurations, or you can order custom designs such as these options:

- Standard V

- Vari Depth V

- Hi/Lo V

- Scalloped

- Peg Style

- Slant Tooth

- Double Double Sharp

You can order standard or custom designed circular knife blades from York Saw & Knife in the same material grades as you’d get in straight blades or other designs. You also have the benefit of working with engineers who will assess your correct material hardness and toughness. That’s a core concept in assuring the cleanest cuts you can make. Some industries that commonly use circular knives manufactured by York Saw & Knife include:

Multiple industries choose circular knives from York Saw & Knife because of a reputation for excellence. That includes material selection, design creativity and customer service. Because all York Saw & Knife products are made in America, you’ll get the best quality. Our blade materials have the U.S.A. seal of approval built into each and every knife.

If circular knives are what you need for your OEM or end user purpose, check out our circular knives. You’ll find interesting information on what’s available on standard products including configurations, styles and materials. You’ll also find suggestions on having custom circular knife blades designed and build for your exacting standards. Give our design team a call today. Together, we can discuss how to make your ideal circular knife a reality for your specific application need.

Cutoff Knives

Cutoff knives are often called guillotine or swing-style cutoff blades. York Saw & Knife cutoff blades are high-quality solutions for packaging, converting and processing applications that serve many industry sectors. They are important tools for businesses in the packaging industry as well as for operations in food processing, glass, leather and fiberglass businesses.

York Saw & Knife designs and manufactures cutoff blades with robust edges. We use superior hardening techniques to keep blades true for the best trimming and cuts that are simple and accurate. Every cutoff knife is built from proven materials such as high carbon steel, stainless steel, solid carbide and ceramics as well as advanced materials like 52100, M-2, D-2 and CPM 10V steel.

You’ll find versatile cutoff blade edge configurations at York Saw & Knife. Besides designing and manufacturing custom knife configurations, we build to supply many industries with existing designs for common application. Some of the different tooth configurations to consider for your cutting application are:

- Standard V, Vari-Depth V and Hi/Low V Profiles

- Scalloped Tooth Configurations

- L-Style Profiles

- Peg Style Configurations

- Slant Tooth Profiles

V-Style profiles are popular because of their countless options in edge geometry and serrations. These guillotine designs are excellent performers on foil, film and paper. Vari-Depth and Hi/Low configurations allow for clean cuts while reducing stress and strain on the cutting machine. You can use Standard V styles for cuts requiring uniform tooth height and Vari-Depth profiles when you want to regulate contact between the material and the cutting edge.

Dissipating your cutting force through different blade designs and configurations is a highly desirable option. This allows you to vary your machine power instead of having to invest in upgraded equipment. Some of the industries using cutoff blade applications from York Saw & Knife are:

Let York Saw & Knife be your custom cutoff blade supplier. You can source stock guillotine or swing-style knife blades for every industry by calling our knife blade professionals today. For more information on cutoff blade styles, materials and configurations, call us today to speak to a York representative about our cutoff blade options, including custom blade manufacturing.

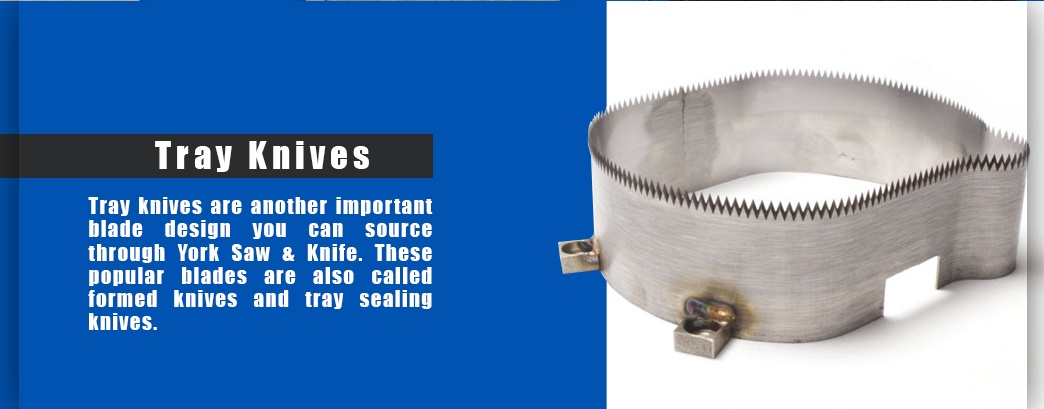

Tray Knives

Tray knives are another important blade design you can source through York Saw & Knife. These popular blades are also called formed knives and tray sealing knives. Our industrial tray knives can be specialty built for OEM manufacturers as reliable and cost-efficient stock cutters. We also offer custom options for end users who need the best available edges for converting and tray-forming actions.

If you’re in the film roll and container industry, our tray knives give you the highest level of precision you can get anywhere. Our tray knives are also excellent for plastic cutting operations. You can expect sharp blades that stay sharp after repeated uses. With York Saw & Knife, you can also get customized shapes and sizes of tooth configurations.

Every tray knife manufactured at York Saw & Knife has the same access to high-grade materials and the professional design team as well as the added benefit of the fastest lead times in the knife-making industry — between 50 to 70 percent faster than our competitors. Plus, you have no minimum order — we ship one or a hundred units, no matter what.

Regardless of what industry your business serves, our engineering team designs and manufactures blades to suit your precise needs. You simply supply us with a blade sample or concept, and we work with you from there. Our quotes are always free, and we cater to many businesses requiring form fill and tray sealing knives. Some of the industries that use tray knives are:

For more information about formed or tray sealing knives, call us to discuss our standard blades. If you’re curious about custom design, York Saw & Knife can help you design and manufacture specialized tray knives and cutting tools.

Fiberglass Cutting Knives

Fiberglass can be a challenging material to cut. As a hard and brittle material, you need a knife that’s capable of delivering a clean cut without the risk of splintering and chipping. You might find that difficult to achieve unless you have the proper equipment such as custom blades designed specifically to handle clean fiberglass cutting. For that, York Saw & Knife can also work out a solution for you no matter your industrial application.

Fiberglass is prevalent in all types of industries from aerospace to automotive manufacturing. It’s also used in boat building and even making bathroom accessories like tubs and showers. For the fiberglass industry, we have a range of fiber chopping and cutting knives as well as tow cutting tools. Whether you require a straight knife for wet/dry chopping, a cutoff knife for cured fiberglass resin or a circular knife for rough fiber work, we have the blades you’ll need.

Because fiberglass is a specialty material, we have specially designed cutters made from high carbon steel, stainless steel and solid carbide. We finish all blades with a protective coating that keeps them sharp for as long as possible. That’s even when cutting problem stock like fiberglass.

Choose York Saw & Knife for Your Industrial Applications

York Saw & Knife is America’s first choice for manufacturing and supplying world class industrial knife blades. For the best economic value in blades and the best customer service in the industrial knife making industry, call York Saw & Knife today. Start investigating your sharpest options for designing custom knives by talking to our team members and requesting a free, no-obligation quote. Call us at 800-233-1969 or reach out to us online today.